Well, I finally got off my sorry arse and decided to try and do something about this thing.

As most of you are aware, the knock against this design is that it is a "tone and volume sucker". That's caused when the saddle is raised and the metal "conveyor" which holds the actual saddle lifts away from the sound board. The only points of vibration transmission left then are the two screws which are still (barely) in contact with the guitar.

In my case, the assembly was already as low as possible so at least the metal was in contact with the sound board. Still, the tone of metal on spruce was not good, neither was there a lot of projection.

I looked at a lot at of possible solutions, the best one being to fill in the wide slot with rosewood and re-cut it for a bone saddle. Unfortunately I don't possess the equipment (or experience) to tackle that sort of precision work And frankly, although this is a nice guitar, it ain't no Martin, ya know? So I'm not paying big bucks to have it done.

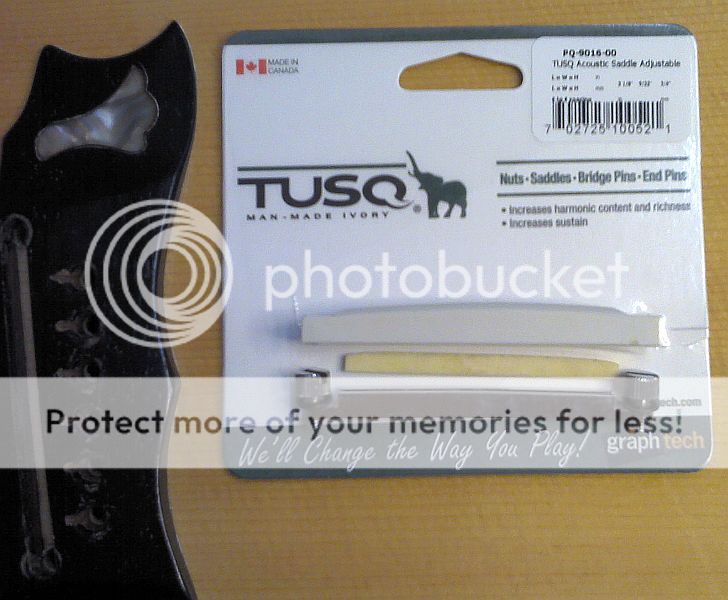

But, I did locate a replacement Tusq saddle designed for a Gibson with a similar adjustable saddle (yup they did this design too, along with a plastic bridge

) So I thought I'd take a chance and see if it could be used.

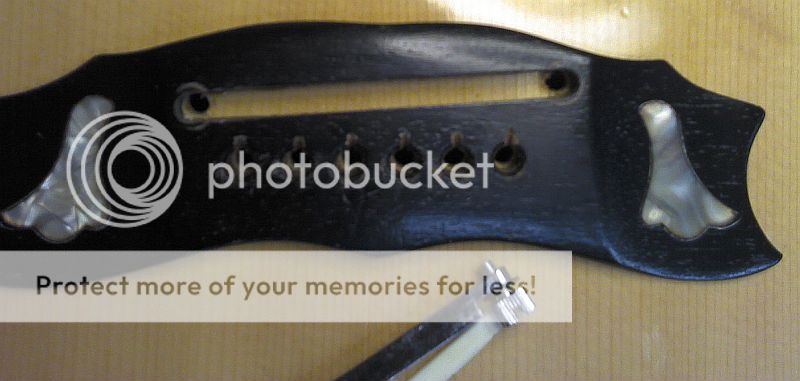

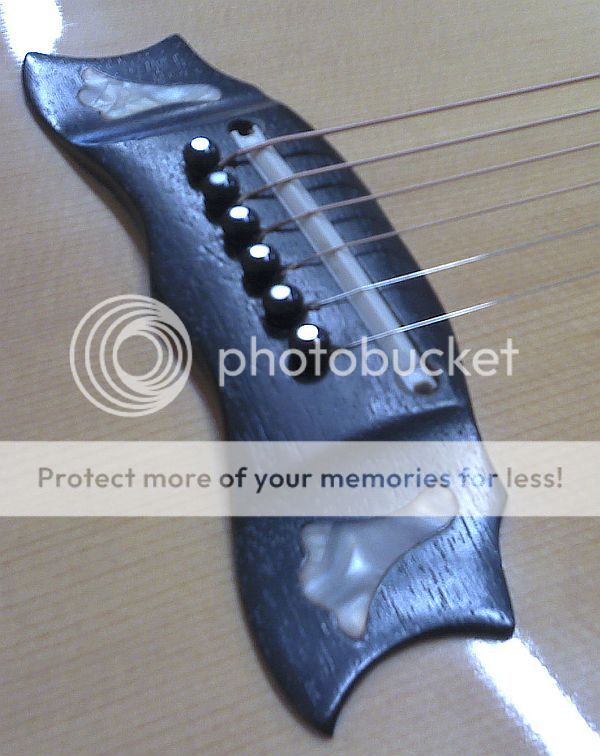

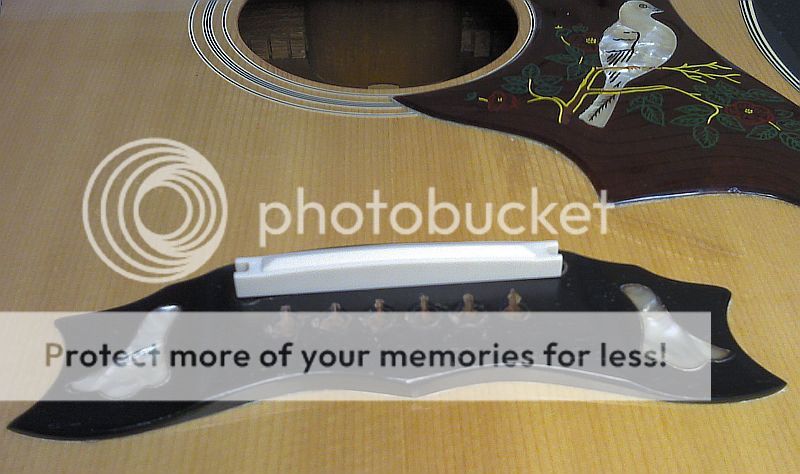

Here's what the old assembly looks like:

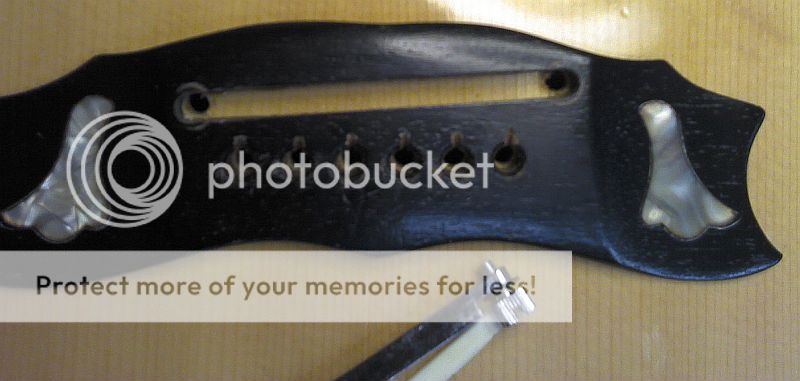

It came out easily, and the sound board surface is clean and sealed. I debated whether to take it down to bare wood but decided it was best to leave the finish on. I was surprised to see that there was no nut assembly under the bridge to fasten the metal to the wood. Many of these designs do have more stuff to remove and they can get a bit complicated to remove. Fortunately not so here. The bolts only screw into the metal bridge and project through the guitar top, hence the two holes.

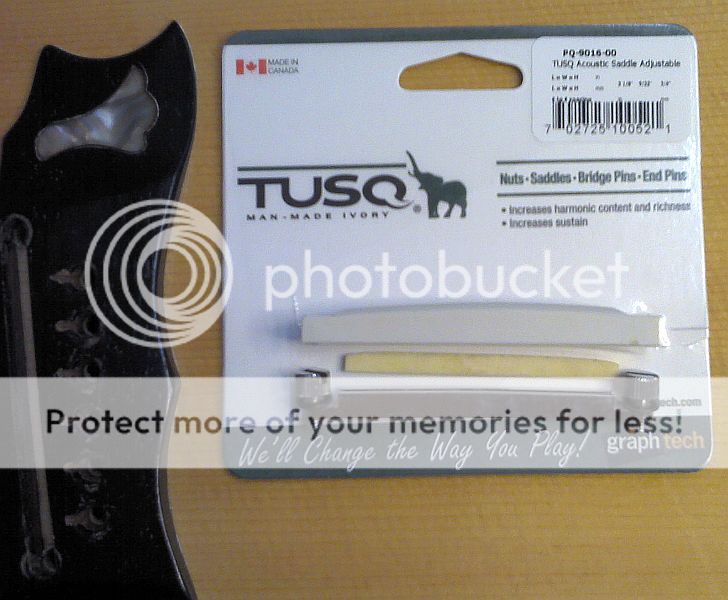

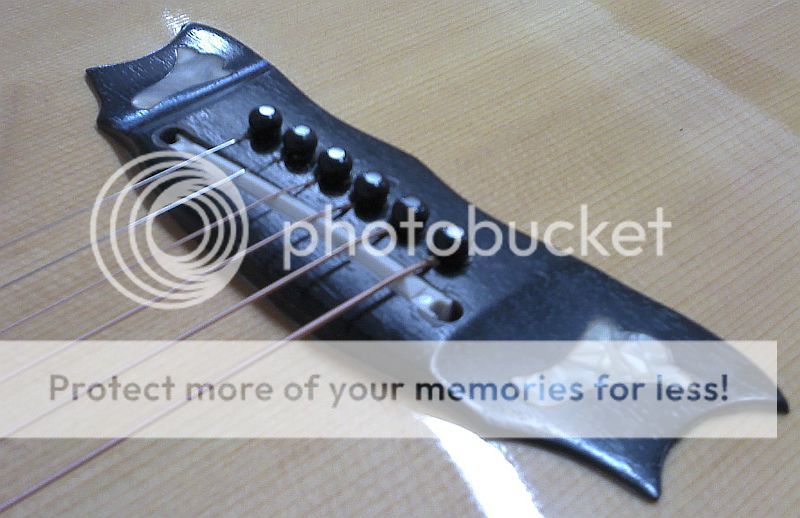

A quick comparison of the old and new:

It isn't a drop-in replacement. It's quite a bit wider, and a tad longer (remember it's for a Gibson):

But it looked very promising, so, out came the ole' sandpaper! The height was fine and didn't require any reduction, in fact it turned out to be a little under height. (adjusted later). In essence I had to sand the excess 'shoulder' width back to the width of the actual saddle. Then it slid into the slot nicely.

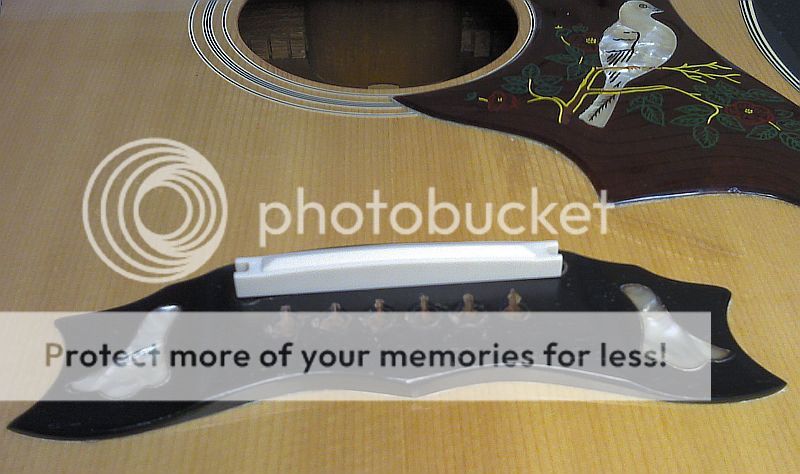

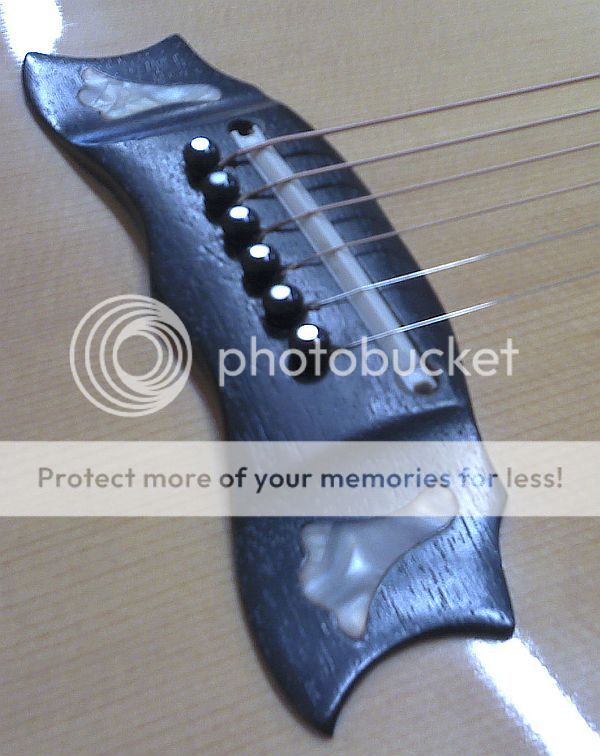

But there were a few issues:

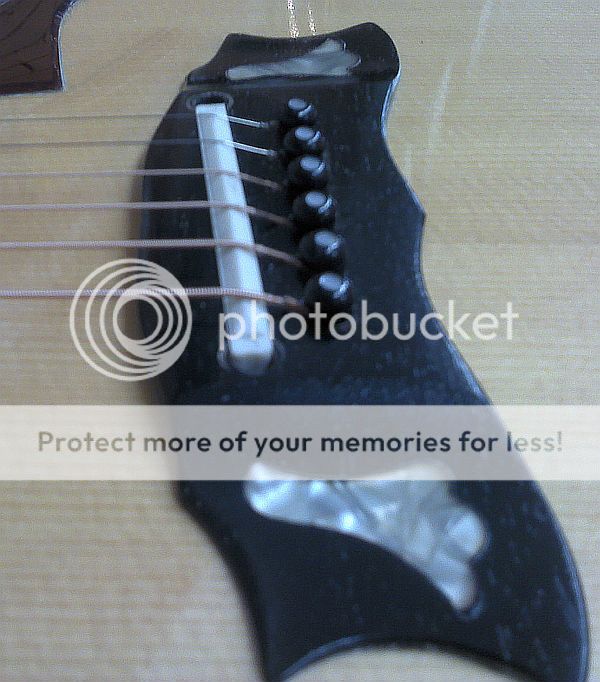

At first glance all is well. But look again and you'll notice that the notches for the bolts are not positioned quite right. No biggie though, since I didn't plan to continue use this as an adjustable saddle. However, a bigger problem is the position of the saddle itself relative to the strings. The bass E is barely on the saddle while the treble E has bags of room! Not good.

The other problem is that the the treble side is too low. So low in fact that there is no break angle at all to the pin on the E string. It's straight through! The result of that was a wonderfully low action on the bass side, but a thin projection on the treble strings.

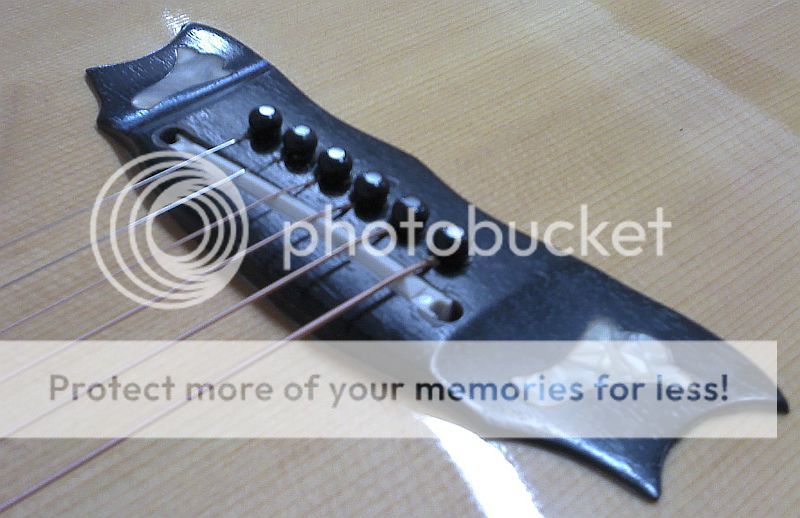

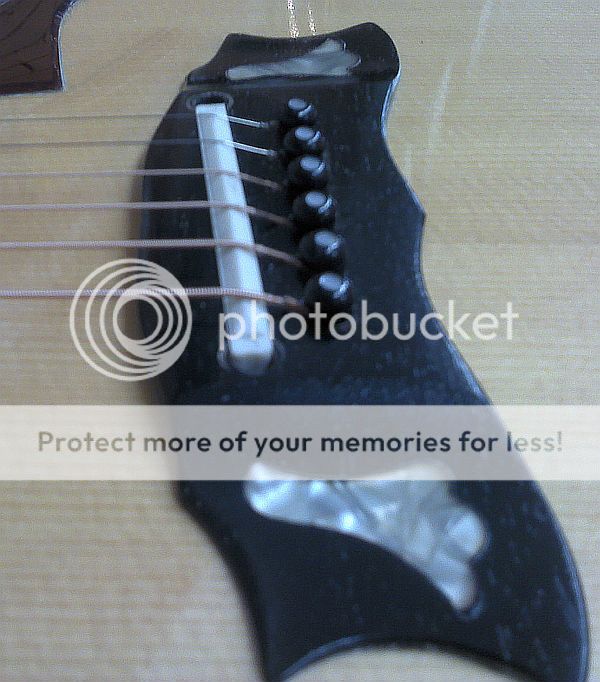

So, two corrections needed (apologies for crappy pix):

1) I removed the end notches completely which allowed me room to reposition the saddle properly under the strings.

2) Then I added a light shim underneath to raise everything enough to increase the break angle and restore energy to the top.

The result? Well, at this stage it won't win any design awards, but let me tell ya, the guitar sounds amazing! Now I can hear the instrument the way it's supposed to be heard. Honestly, the whole guitar is alive and vibrates with a sustain that it has never enjoyed in the almost 40 years that I've had it. I wish I had done it long ago.

What's left to do is purely cosmetic work. I will likely remove any remaining material covering the holes and either reinsert the old bolts (with a touch of white glue to hold them NOT crazy stuff) or, if I get ambitious, I'll plug the holes with a suitable piece of doweling or MOP plug.

At this point I am very happy with the sonic results. What a difference! Highly recommended mod.

) So I thought I'd take a chance and see if it could be used.

) So I thought I'd take a chance and see if it could be used.